The basis of our precision engineering

System structure

- precise aluminum profiles in grid 25, 40, 50

- high-strength profiles due to special alloys

- torsion-resistant system

- Profiles completely equipped with grid holes

- Connections through the use of face shims and pin bushings with form and force fit

- Stable, extensive connection system and coordinated accessories

- Always available stock

- High sustainability through reuse / re-tooling of devices

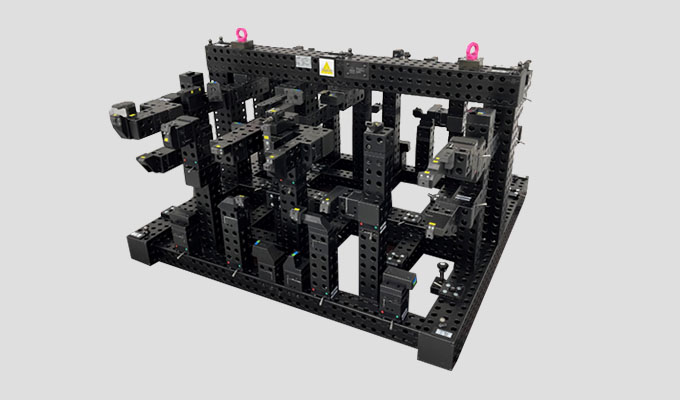

Is ideal in the application for flexible setups for measurement recordings. These find their application, e.g., in small series, in the analysis or in the prototype construction, with which no series recordings are provided, in addition, in the training and/or in laboratories.

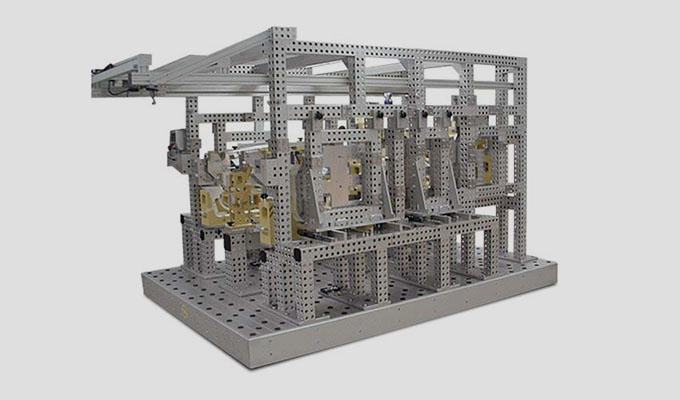

The Paletti precision system is designed for modular, flexible setup of measuring fixtures. This concept allows the fixtures to be created in a cost-efficient, reproducible manner, and retooling is also possible, so this additionally conserves resources and increases cost-effectiveness.

Our standard components form the basis for gauges and analysis devices. These can also be reused several times, so that highly flexible but also cost-effective fixtures can be created by exchanging the test flanges. We can also make conventional gauges in aluminum or plastic according to customer requirements.

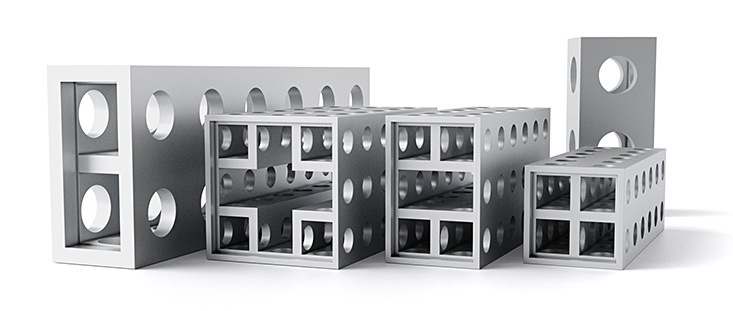

When the highest accuracy is required, Paletti’s master blocks are the first choice. Torsionally stiff, highly precise and individually adaptable thanks to a wide range of accessory components. Components from a wide variety of areas can be fixed and joined in this way. Thus, Paletti Meisterböcke are the ideal tool to support your production in the vehicle start-up.

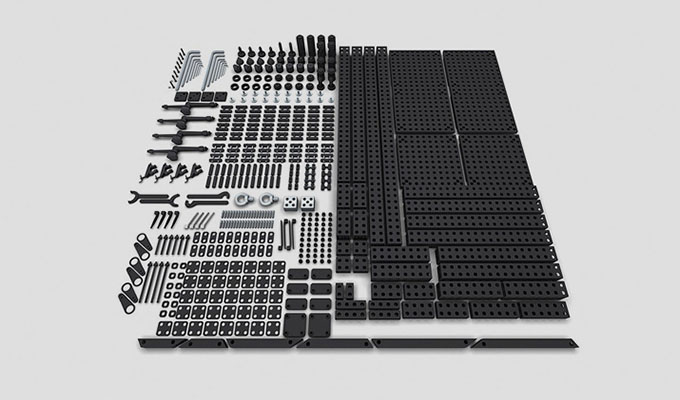

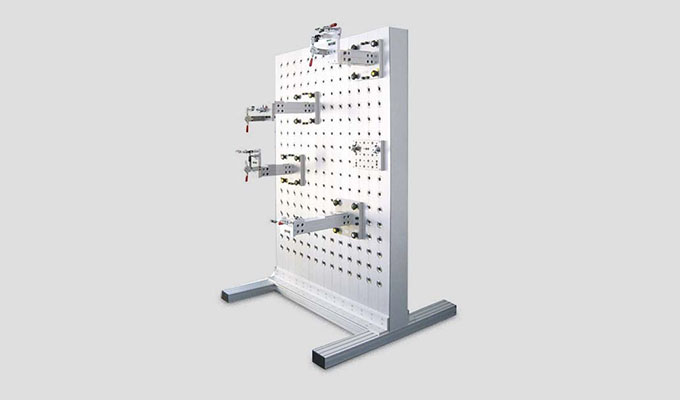

Our perforated grid plates or base frame systems are the ideal basis for the flexible construction of measuring fixtures and devices. They are made of aluminum and are available in natural or black anodized.