Prozesstore, Hubtore, Schiebetore & Drehtischabdichtungen

So sicher wie die KabineDamit die Arbeit in einer Schutzkabine prozesssicher und ohne große Verzögerungen stattfinden kann, muss gewährleistet sein, dass die zu bearbeitenden Bauteile problemlos in das Kabineninneren herein- und herausgeschleust werden können. Und genau das stellen unsere Prozess-, Hub- und Schiebetore sicher, die im Baukastensystem an quasi jeder beliebigen Stelle der Laserschutzkabine montiert werden können.

Produkte

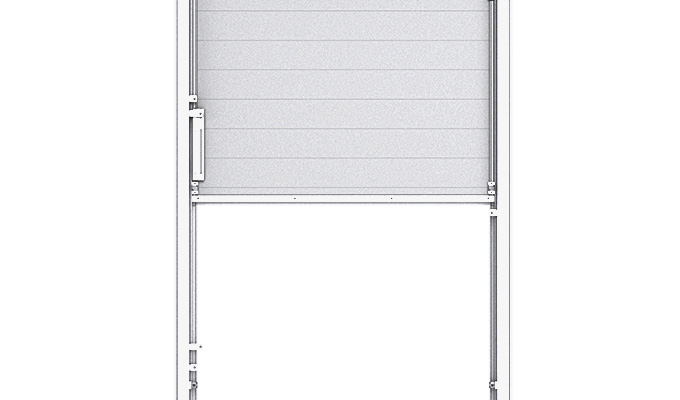

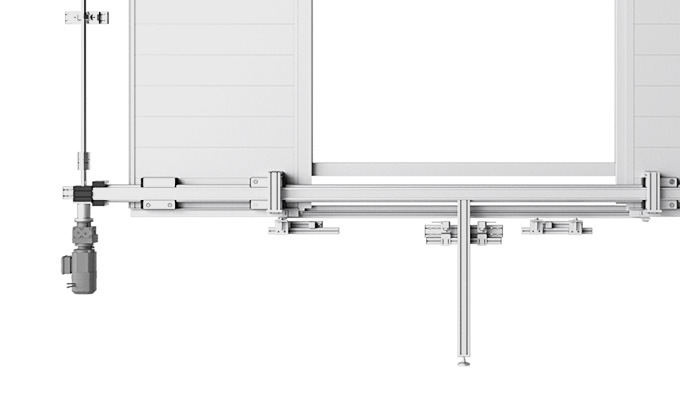

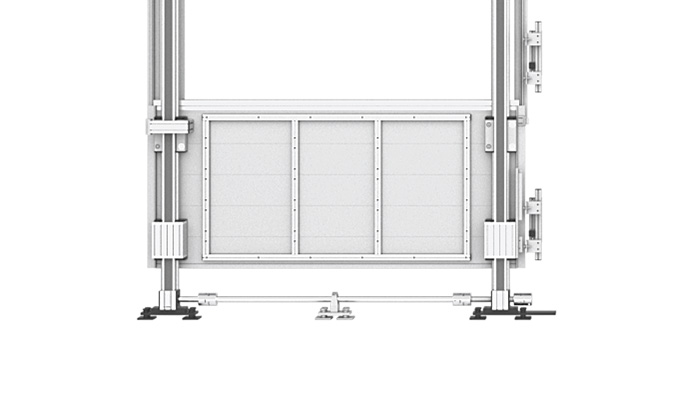

Dank der verwendeten Profile ist das Hubtor absolut lichtdicht. Verirrte Laserstrahlen laufen sich in dem labyrinthartigen Aufbau tot und können außerhalb der Kabine keinen Schaden anrichten. Die Motoranbindung zum Öffnen und Schließen des Tores kann, je nach Einsatzzweck, wahlweise oben oder unten erfolgen.

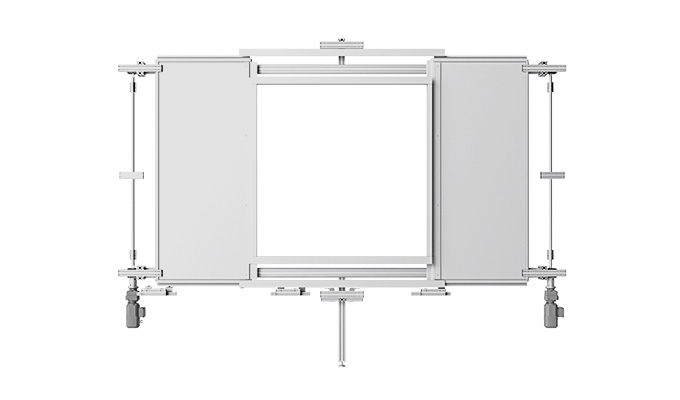

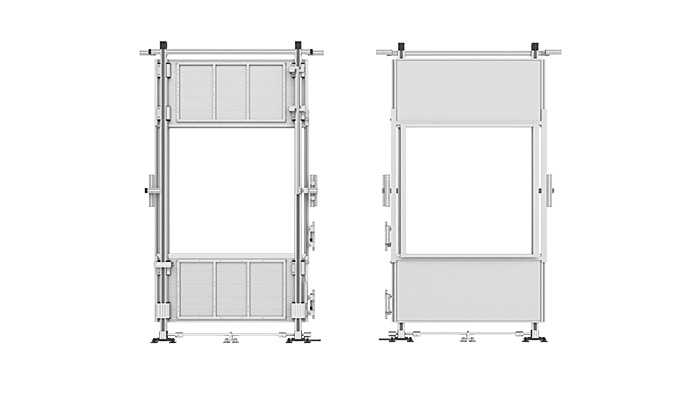

Ein Schiebeprozesstor wird hauptsächlich dann eingesetzt, wenn es die Prozessabläufe oder die Platzverhältnisse erfordern. Wegen der kürzeren Fahrzeit eines Flügels sind diese Tore unter Umständen schneller zu öffnen und zu schließen als ein Hubtor. Durch den Einsatz doppelflügliger Prozesstore reduziert sich die Öffnungs- und Schließzeit deutlich.

Um ein vertikales Prozesstor zu bewegen wird, anders als beim Hubtor, kein Gegengewicht benötigt. Der Antrieb muss lediglich die Reibung und die Massenträgheit des Tores überwinden, weshalb dieses Tor sehr energieeffizient betrieben werden kann.

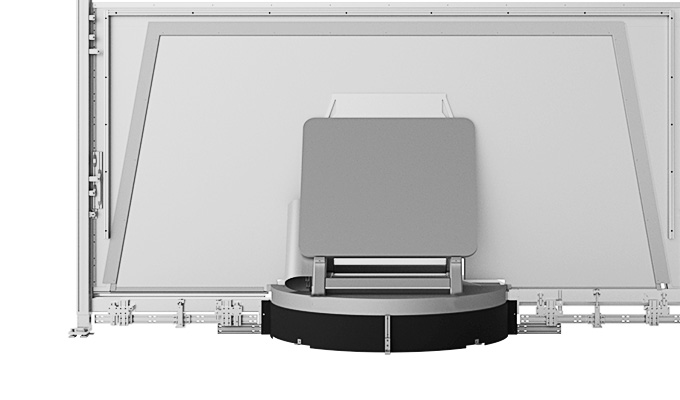

Wir liefern doppeltwirkende Hubtore, Verkleidungen für Drehtische und komplette Drehsysteme für unterbrechungsfreien Lasereinsatz.

Jetzt Kontakt aufnehmen

Immer auf dem LaufendenSie haben eine Frage? Eine Anregung? Oder einen Auftrag? Zögern Sie nicht, sich bei uns zu melden. Ob per Mail oder mit einem Anruf – unsere Experten freuen sich, Ihnen rund um das Thema Aluminiumprofile weiterzuhelfen.