Linearsysteme mit Zahnriemenantrieb

Für hohe Geschwindigkeit und lange Verfahrwege, ideal für Handlings- und Positionieraufgaben geeignet. Lange Lebensdauer, geräusch- und wartungsarm sowie aufgrund der Geometrie mit Nutsystem gut integrierbar – auch in Mehrachssysteme.

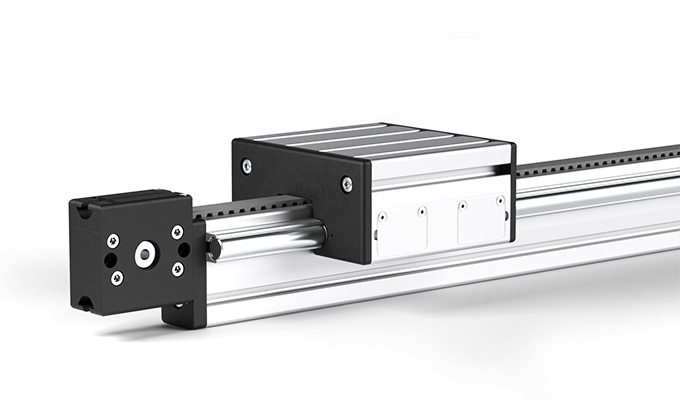

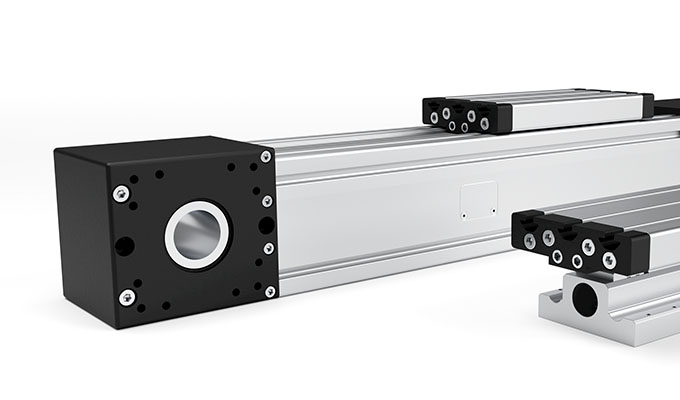

Das Linearachsensystem 16 basiert auf einer großen Anzahl von Führungsprofilen mit integrierter Wellenklemmung, gehärteten und geschliffenen 16-mm-Stahlwellen sowie unterschiedlichen Laufwagenprofilen. In Kombination mit entsprechenden Zahnriemenumlenkungen lassen sich nach Kundenwunsch Linearachsen fertigen, die sowohl den Ansprüchen an die Belastung, den Einsatz von mehreren Laufrollen als auch in der Ausführung den Anforderungen entsprechen.

- Baugrößen: 40 x 40, 40 x 80 / 40, 40 x 80 / 80, 80 x 80, 80 x 120, 80 x 120 8N, 120 x 120 / 80

- Antriebsvariante: Zahnriemenantrieb

- Führungsvariante: Rollenführung

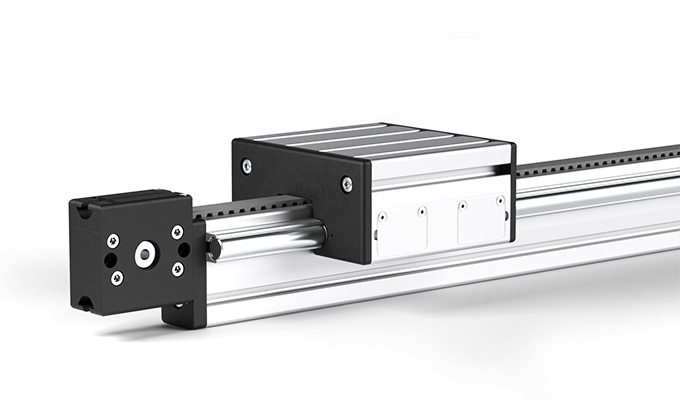

Die Zahnriemengegenumlenkungen werden für Zahnriemen AT 10/22 und AT 10/50 gefertigt. Gegenumlenkungen ermöglichen die Verlagerung des Antriebs vom Ende einer Achse auf den Laufwagen. Damit wird der Laufwagen zum ortsfesten Element der Konstruktion und die Achse selbst wird bewegt. In unserem Standardprogramm führen wir Gegenumlenkungen mit integrierten Laufwagen und Gegenumlenkungen ohne Laufwagen für den speziellen Kundeneinsatz. Häufiger Einsatz auch bei Mehrachssystemen.

- Baugrößen: Teleskopachse 16

40 x 80 / 80 + 40 x 80 / 80 / 200 / G 50

Linearachse 16

40 x 80 / 40 / G 22, 80 x 80 / G 50, 40 x 80 / 80 + 40 x 80 / 80 / G 50, 80 x 80 + 40 x 80 / 80 / G 50 - Antriebsvariante: Zahnriemenantrieb

- Führungsvariante: Rollenführung

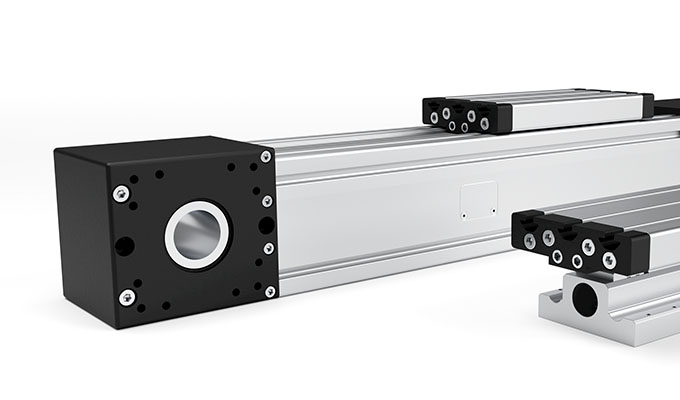

Das Linearachsensystem 25 basiert auf einer großen Anzahl von Führungsprofilen mit integrierter Wellenklemmung, gehärteten und geschliffenen 25-mm-Stahlwellen sowie unterschiedlichen Laufwagen. In Kombination mit entsprechenden Zahnriemenumlenkungen lassen sich nach Kundenwunsch Linearachsen fertigen, die sowohl den Ansprüchen an die Belastung, den Einsatz von mehreren und verschiedenen Laufrollen als auch in der Ausführung den Anforderungen entsprechen.

- Baugrößen: 40 x 40, 80 x 80, 80 x 160, 120 x 120

- Antriebsvariante: Zahnriemenantrieb

- Führungsvariante: Rollenführung

Die innenliegende Führung 80 x 100 wird durch eine interne 15er- sowie die Führung 120 x 150 durch eine 25er-Kugelschienenführung geführt. In Verbindung mit der Zahnriemenumlenkung 40/40 beim Führungsprofil 80/100 kommt der Zahnriemen AT 10/22 bzw. mit der Zahnriemenumlenkung 80/120 beim Führungsprofil 120 x 120 der Zahnriemen AT 10/50 zum Einsatz.

- Baugrößen: 80 x 100, 120 x 150

- Antriebsvariante: Zahnriemenantrieb

- Führungsvariante: Kugelschienenführung

Die innenliegende Doppelführung 120 x 150 wird durch zwei interne 15er-Kugelschienenführung geführt. Das System wird durch einen Zahnriemen angetrieben und ist wartungsfrei. Zum Schutz der innenliegenden Führungen gegen Verschmutzung wird das Profil durch den Zahnriemen geschlossen. In Verbindung mit der Zahnriemenumlenkung 80 x 120 beim Führungsprofil 120 x 150 kommt der Zahnriemen AT 10/50 zum Einsatz.

- Baugrößen: 120 x 150

- Antriebsvariante: Zahnriemenantrieb

- Führungsvariante: Kugelschienenführung

Einzelführung oder Doppelführung, kann durch ihre besondere Rollenführung unter einem beliebigen Winkel betrieben werden und ist wartungsfrei. In Verbindung mit der Zahnriemenumlenkung 80/90 bzw. 80/80 kommt der Zahnriemen AT 10/50 zum Einsatz. Die Doppelführung bietet zudem auf beiden Seiten Aufnahmemöglichkeiten durch zwei Laufwagen.

- Baugrößen: 80/90 Einzelführung, 80/90 Doppelführung, 120×120 AT10/75 Kunststoffrollen, 120×120 AT10/75 Stahlrollen

- Antriebsvariante: Zahnriemenantrieb

- Führungsvariante: Rollenführung

Das C-Linearachsensystem basiert auf einer großen Anzahl von Führungs- und Laufwagenprofilen. Es werden Kunststofflaufrollen aus POM eingesetzt, die direkt in dem Aluminiumprofil laufen. Für die einzelnen Führungsprofile werden die zugehörigen Umlenkeinheiten für Zahnriemenantrieb gefertigt. Die Zahnriemenumlenkungen werden für die Zahnriemen AT 3/10 und AT 5/16 und AT 10/22 gefertigt. Der Anschluss des Motors erfolgt über einen Stahleinsatz Ihrer Wahl. Der Anbau des Motors erfolgt entweder direkt oder über eine Kupplung oder über ein Zahnriemengetriebe. Erforderliche Flanschplatten oder Kupplungsglocken fertigen wir nach Ihren Wünschen.

- Baugrößen: C 40 x 57, C 40 x 100, C 80 x 100, C 80 x 100 Doppelführung

- Antriebsvariante: Zahnriemenantrieb

- Führungsvariante: Rollenführung

C-Führungen mit Kunststoffrollen. Durch die Erhöhung der Rollenanzahl werden die zulässigen Belastungswerte des Systems erhöht. C-Führungen benötigen keine Schmierung und sind eine kostengünstige Alternative zu Stahlführungen.

- Baugrößen: C 80 x 100 mit Gegenumlenkung

- Antriebsvariante: Zahnriemenantrieb

- Führungsvariante: Rollenführung

Das Linearachsensystem 16 basiert auf einer großen Anzahl von Führungsprofilen mit integrierter Wellenklemmung, gehärteten und geschliffenen 16-mm-Stahlwellen sowie unterschiedlichen Laufwagenprofilen. In Kombination mit entsprechenden Zahnriemenumlenkungen lassen sich nach Kundenwunsch Linearachsen fertigen, die sowohl den Ansprüchen an die Belastung, den Einsatz von mehreren Laufrollen als auch in der Ausführung den Anforderungen entsprechen.

- Baugrößen: 40 x 40, 40 x 80 / 40, 40 x 80 / 80, 80 x 80, 80 x 120, 80 x 120 8N, 120 x 120 / 80

- Antriebsvariante: Zahnriemenantrieb

- Führungsvariante: Rollenführung

Die Zahnriemengegenumlenkungen werden für Zahnriemen AT 10/22 und AT 10/50 gefertigt. Gegenumlenkungen ermöglichen die Verlagerung des Antriebs vom Ende einer Achse auf den Laufwagen. Damit wird der Laufwagen zum ortsfesten Element der Konstruktion und die Achse selbst wird bewegt. In unserem Standardprogramm führen wir Gegenumlenkungen mit integrierten Laufwagen und Gegenumlenkungen ohne Laufwagen für den speziellen Kundeneinsatz. Häufiger Einsatz auch bei Mehrachssystemen.

- Baugrößen: Teleskopachse 16

40 x 80 / 80 + 40 x 80 / 80 / 200 / G 50

Linearachse 16

40 x 80 / 40 / G 22, 80 x 80 / G 50, 40 x 80 / 80 + 40 x 80 / 80 / G 50, 80 x 80 + 40 x 80 / 80 / G 50 - Antriebsvariante: Zahnriemenantrieb

- Führungsvariante: Rollenführung

Das Linearachsensystem 25 basiert auf einer großen Anzahl von Führungsprofilen mit integrierter Wellenklemmung, gehärteten und geschliffenen 25-mm-Stahlwellen sowie unterschiedlichen Laufwagen. In Kombination mit entsprechenden Zahnriemenumlenkungen lassen sich nach Kundenwunsch Linearachsen fertigen, die sowohl den Ansprüchen an die Belastung, den Einsatz von mehreren und verschiedenen Laufrollen als auch in der Ausführung den Anforderungen entsprechen.

- Baugrößen: 40 x 40, 80 x 80, 80 x 160, 120 x 120

- Antriebsvariante: Zahnriemenantrieb

- Führungsvariante: Rollenführung

Einzelführung oder Doppelführung, kann durch ihre besondere Rollenführung unter einem beliebigen Winkel betrieben werden und ist wartungsfrei. In Verbindung mit der Zahnriemenumlenkung 80/90 bzw. 80/80 kommt der Zahnriemen AT 10/50 zum Einsatz. Die Doppelführung bietet zudem auf beiden Seiten Aufnahmemöglichkeiten durch zwei Laufwagen.

- Baugrößen: 80/90 Einzelführung, 80/90 Doppelführung, 120×120 AT10/75 Kunststoffrollen, 120×120 AT10/75 Stahlrollen

- Antriebsvariante: Zahnriemenantrieb

- Führungsvariante: Rollenführung

Das C-Linearachsensystem basiert auf einer großen Anzahl von Führungs- und Laufwagenprofilen. Es werden Kunststofflaufrollen aus POM eingesetzt, die direkt in dem Aluminiumprofil laufen. Für die einzelnen Führungsprofile werden die zugehörigen Umlenkeinheiten für Zahnriemenantrieb gefertigt. Die Zahnriemenumlenkungen werden für die Zahnriemen AT 3/10 und AT 5/16 und AT 10/22 gefertigt. Der Anschluss des Motors erfolgt über einen Stahleinsatz Ihrer Wahl. Der Anbau des Motors erfolgt entweder direkt oder über eine Kupplung oder über ein Zahnriemengetriebe. Erforderliche Flanschplatten oder Kupplungsglocken fertigen wir nach Ihren Wünschen.

- Baugrößen: C 40 x 57, C 40 x 100, C 80 x 100, C 80 x 100 Doppelführung

- Antriebsvariante: Zahnriemenantrieb

- Führungsvariante: Rollenführung

C-Führungen mit Kunststoffrollen. Durch die Erhöhung der Rollenanzahl werden die zulässigen Belastungswerte des Systems erhöht. C-Führungen benötigen keine Schmierung und sind eine kostengünstige Alternative zu Stahlführungen.

- Baugrößen: C 80 x 100 mit Gegenumlenkung

- Antriebsvariante: Zahnriemenantrieb

- Führungsvariante: Rollenführung

Die innenliegende Führung 80 x 100 wird durch eine interne 15er- sowie die Führung 120 x 150 durch eine 25er-Kugelschienenführung geführt. In Verbindung mit der Zahnriemenumlenkung 40/40 beim Führungsprofil 80/100 kommt der Zahnriemen AT 10/22 bzw. mit der Zahnriemenumlenkung 80/120 beim Führungsprofil 120 x 120 der Zahnriemen AT 10/50 zum Einsatz.

- Baugrößen: 80 x 100, 120 x 150

- Antriebsvariante: Zahnriemenantrieb

- Führungsvariante: Kugelschienenführung

Die innenliegende Doppelführung 120 x 150 wird durch zwei interne 15er-Kugelschienenführung geführt. Das System wird durch einen Zahnriemen angetrieben und ist wartungsfrei. Zum Schutz der innenliegenden Führungen gegen Verschmutzung wird das Profil durch den Zahnriemen geschlossen. In Verbindung mit der Zahnriemenumlenkung 80 x 120 beim Führungsprofil 120 x 150 kommt der Zahnriemen AT 10/50 zum Einsatz.

- Baugrößen: 120 x 150

- Antriebsvariante: Zahnriemenantrieb

- Führungsvariante: Kugelschienenführung

Jetzt Kontakt aufnehmen

Immer auf dem LaufendenSie haben eine Frage? Eine Anregung? Oder einen Auftrag? Zögern Sie nicht, sich bei uns zu melden. Ob per Mail oder mit einem Anruf – unsere Experten freuen sich, Ihnen rund um das Thema Aluminiumprofile weiterzuhelfen.